Drylining is a critical aspect of construction, whether for residential, commercial, or industrial projects. Choosing the right materials ensures durability, aesthetic appeal, and long-term success. At CB Building Products, we understand the complexities of selecting the best drylining materials, including plasterboards, adhesives, and performance boards. This guide will walk you through key considerations for your project to ensure efficient and high-quality results.

Why Is Choosing the Right Drylining Materials Important?

Selecting the right drylining materials impacts multiple aspects of your project:

- Durability: Using high-quality plasterboards ensures a longer lifespan and fewer repairs.

- Efficiency: Proper materials simplify installation, saving time and labour.

- Performance: Tailored solutions like performance boards enhance insulation, soundproofing, and fire resistance.

Understanding Drylining Materials

Before diving into tips, it’s essential to understand the core components of drylining:

1. Plasterboards

Plasterboards form the foundation of drylining. They are lightweight yet sturdy, offering a smooth finish for painting or wallpapering. Types of plasterboards include:

- Standard Plasterboards: Ideal for walls and ceilings in dry environments.

- Moisture-Resistant Boards: Designed for bathrooms and kitchens to prevent mould growth.

- Fire-Resistant Boards: Essential for areas requiring enhanced fire safety, such as stairwells or garages.

- Acoustic Plasterboards: Reduce noise transfer, perfect for shared walls in offices or flats.

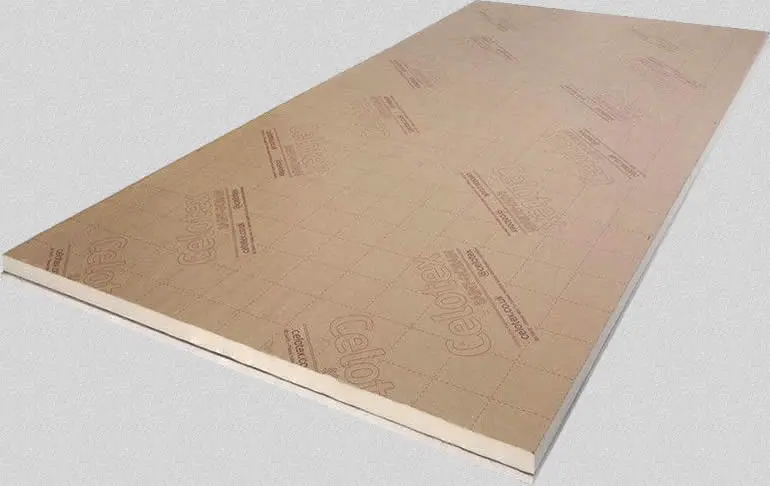

2. Performance Boards

Performance boards are specialised materials that offer additional benefits like insulation or strength. These boards combine durability with functionality, making them suitable for high-performance applications. Common options include:

- Thermal Boards: Enhance insulation and improve energy efficiency.

- Impact-Resistant Boards: Designed for high-traffic areas to withstand wear and tear.

- Multi-Functional Boards: Combine properties like fire resistance and soundproofing.

3. Drylining Adhesives

Drylining adhesives secure plasterboards to walls or frames. Selecting the right adhesive ensures stability and reduces the risk of issues like sagging. Types include:

- General-Purpose Adhesives: Versatile and suitable for standard boards.

- Specialist Adhesives: Tailored for moisture or fire-resistant boards.

Tips for Choosing the Best Drylining Materials

1. Assess Your Project’s Requirements

Every project is unique. Consider the environment, purpose, and structural demands. For example:

- Use moisture-resistant boards in wet areas like bathrooms.

- Opt for acoustic plasterboards in shared living or working spaces.

- Choose thermal boards for improved insulation in energy-efficient builds.

2. Prioritise Quality

Investing in high-quality materials ensures durability and reduces long-term costs. At CB Building Products, we source products from trusted brands like British Gypsum and Knauf, known for their reliability.

3. Consult Experts

If you’re unsure which materials suit your project, seek professional advice. Our experienced team at CB Building Products offers guidance tailored to your specific needs.

4. Consider Environmental Impact

Sustainable building practices are increasingly important. Look for eco-friendly plasterboards and adhesives that minimise environmental impact while meeting performance standards.

5. Plan for Efficient Delivery

Timely delivery keeps your project on track. CB Building Products provides fast, reliable delivery nationwide, ensuring you have the materials you need when you need them.

Common Applications of Drylining Materials

Drylining is versatile and suited for various applications, including:

- Residential Projects: Create smooth, paintable walls and ceilings.

- Commercial Spaces: Use performance boards for fire safety and soundproofing.

- Industrial Buildings: Opt for impact-resistant boards in high-traffic areas.

Mistakes to Avoid When Choosing Drylining Materials

- Ignoring Environmental Conditions: Using standard boards in wet areas leads to mould and damage.

- Overlooking Performance Needs: Failing to use acoustic or thermal boards can compromise comfort and efficiency.

- Choosing Low-Quality Adhesives: Poor adhesives can cause instability, increasing maintenance costs.

- Skipping Expert Advice: Incorrect material selection can lead to costly delays and rework.

FAQs

What Are the Best Drylining Materials for HighMoisture Areas?

Moisture-resistant plasterboards are ideal for bathrooms, kitchens, and basements. These boards prevent mould growth and structural damage, ensuring long-term durability.

How Do I Know Which Performance Board Is Right for My Project?

Consider your project’s needs. For soundproofing, choose acoustic boards. For insulation, opt for thermal boards. CB Building Products provides expert advice to help you select the right materials.

Do You Offer Delivery for Large Drylining Orders?

Yes, CB Building Products provides reliable nationwide delivery. Whether your order is small or bulk, we ensure materials arrive on time to keep your project on schedule.

How Can I Ensure Proper Adhesive Selection for My Drylining Project?

Select adhesives tailored to your boards. For example, use specialist adhesives for moisture-resistant or fire-rated boards. Our team can recommend the best options for your needs.

Conclusion

Choosing the right drylining materials for construction is crucial for project success. From high-quality plasterboards and performance boards to reliable adhesives, CB Building Products offers everything you need. Our expert team provides tailored advice, ensuring your materials meet your project’s unique demands.

Ready to get started?

Visit CB Building Products To explore our range of drylining solutions and make your next project a success.